Q: What temperature should I set my dryer at?

A: I don’t know.

That’s the best answer to that question. Another answer is to say, “whatever temperature raises the ink film temperature to 320 degrees for ten seconds.” Curing ink will be affected by the ambient temperature, how long your drying chamber is, the height of your heating elements, whether it is gas or electric, air flow, ink thickness, ink color, garment color, the load in the dryer… and the moisture in the garment.

I dare you to measure the moisture content in a garment. I have never been in a facility that can do that.

We’ll start with two anecdotes:

- Andy Anderson was telling me that with nice thick shirts that he knows are coming from a moisture laden environment, he gets approximately a 25% reduction in production. The cause is longer flash times and longer time in the oven to get a proper cure.

- Every Spring Rutland Ink gets a lot more calls about ink curing difficulties. “Our dryer is set the same as always and everything is the same but the ink isn’t curing. It must be defective…” Reply: “Has either it been raining there, or could the shirts have come from a warehouse where it was raining?”

If there is moisture in your shirts (or even worse in canvas) it will evaporate when you apply heat. As the moisture evaporates it will cool down the surface of the garment, this will counteract the heat for curing the ink.

What can you do?

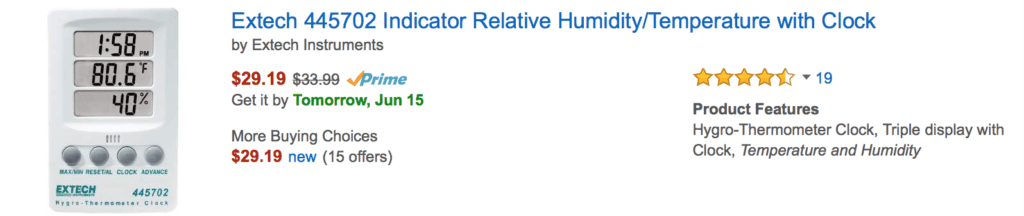

- Condition the shirts by getting them out of the box and into our shop if your shop is air conditioned or if the air is dry. You measure humidity of the room with a gauge which you can buy at a hardware store or on line, you cannot just “feel it.”

- You probably have to turn your belt speed down to give the garment more time to have the moisture evaporate.

- More time is better than more temperature, but if you can avoid scorching the garment you can turn up the temperature to overcome humidity in the shirts.

- In extreme case of high humidity or if you have a very short dryer chamber, you may have to run the shirts through the dryer before you print them, or put them through twice.

- Just because you are in a dry area doesn’t mean you don’t have moisture in the garments. Where did the shirts come from either before the boxes were sealed up, or where they were warehoused. See #1 above.

- Garment dyed shirts are particularly prone to humidity issues since the process involved my leave residual moisture in the shirts.

There are many ways to determine whether ink is curing on a garment. The best one is to wash it and see if the ink cracks or comes off. Test your shirts more often during the rainy season.

Comments