We have posted before on the Ink Kitchen on what you can do about ink spots on garment dyed shirts. Check it out here. The short answer, is “not much.” The shirts are wonderful and customers love the feel and the colors, but the dye system that makes them wonderful also gives printers problems. One of those problems is that cured plastisol ink cannot usually be removed without also removing the dye.

So really you want to avoid ink spots and here are some of the best ways to do it.

- Make sure you closely examine your screens and block out not just any holes, but any places that look thin.

- A basic thing is to use good quality emulsion and make sure you have tested it and have the ideal exposure time. If it is an emulsion that can be secondarily hardened by post exposing, make sure you do that.

- Take more care when you tape up your screens, and if you don’t usually tape your screens consider taping your screens when you are printing garment dyed shirts.

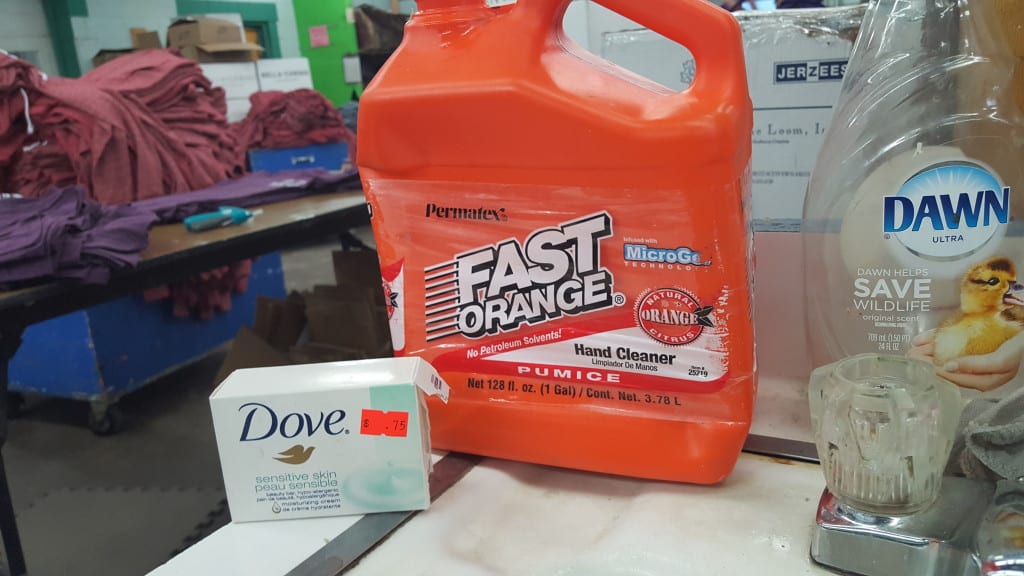

- Make sure your workers clean their hands and arms thoroughly before starting on working with garment dyed shirts and maybe wear aprons that you run through the dryer before starting so there is no random ink on anyone.

- Make sure your press and press area are super clean before you start.

- Make sure you thoroughly block out and/or tape out your registration marks.

Wash your hands!

Comments