As outlined in the earlier posts, you can heat up the polyester garment in question with a heat press and a drop of plasticizer will cause some dye to transfer to a piece of white jersey. Pretty much all fabric will transfer some of the dye, but it is a matter of degree. The more testing you do, the better idea you will have of what is an indication of how far you have to go to prevent dye migration.

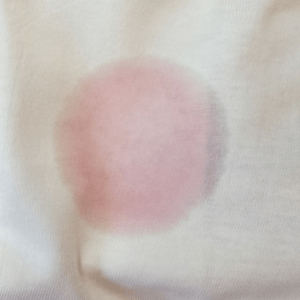

Here are three test dots we did on maroon colored 100% polyester shirts.

There is almost no dye transferred on the first shirt we printed so we figure that it probably could even be printed with ink for cotton, but we use an ink made for 50/50’s, in our case Rutland Snap White.

The second shirt shirt shows more transfer of the dye, and more potential problems, but actually doesn’t show all that much dye transfer. We probably could get buy using a 50/50 ink, but to be safe we would use a polyester ink, in our case Rutland Super Poly White.

The third shirt shows dramatic dye transfer when heated with plasticizer. This shirt is a “bleeder.” I would avoid a shirt like this if possible. Of course since we are contract printers, we don’t get to avoid shirts usually. In this case we would print a first down blocker, in our shop that is Rutland Barrier Base (formerly Dyno Grey.) We would also put a Poly White as the one of two top coats of ink.

Comments