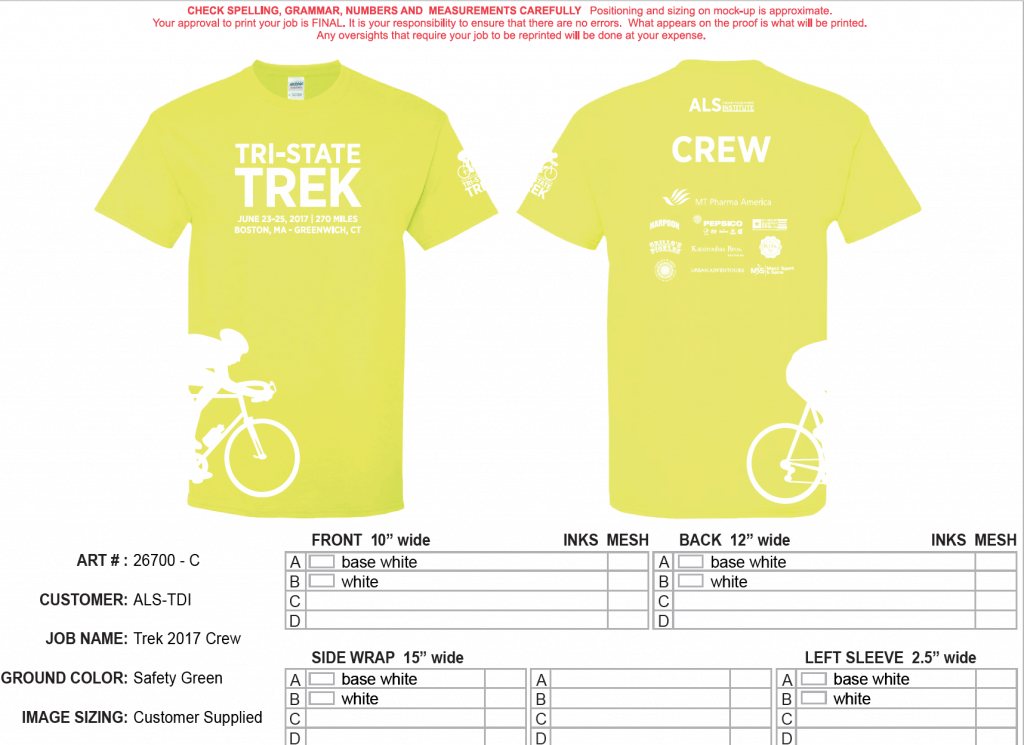

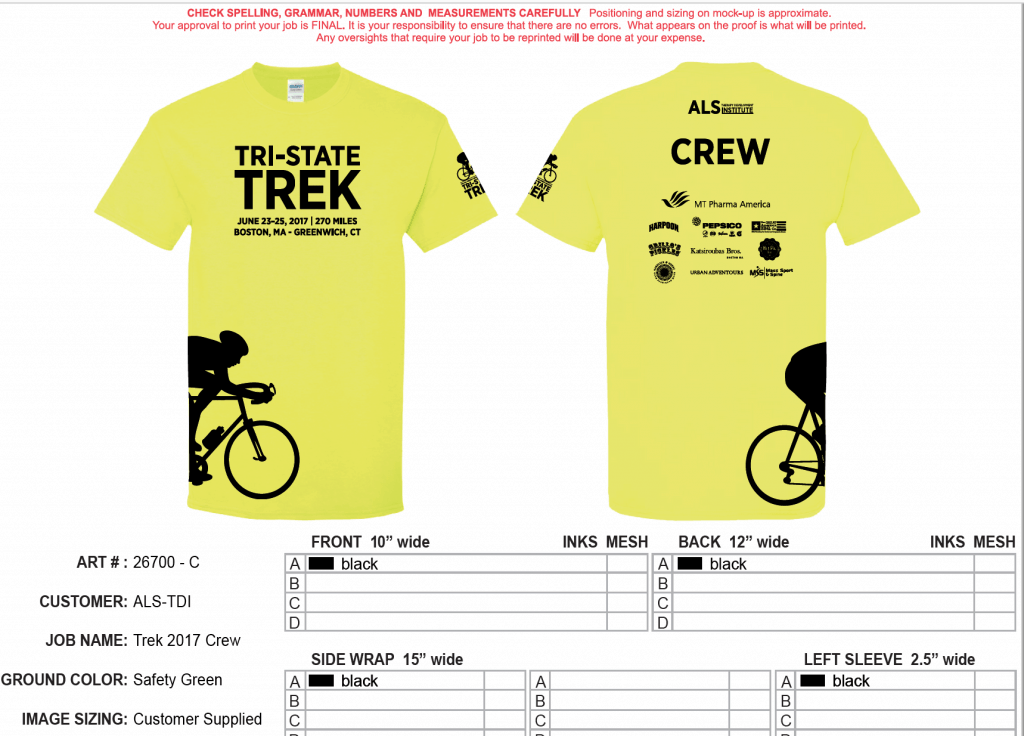

We recently mocked up a job on lime green shirts with white ink. Not super high contrast but it looked ok. The customer approved the mock up, and the customer had seen the blank shirts in this color before.

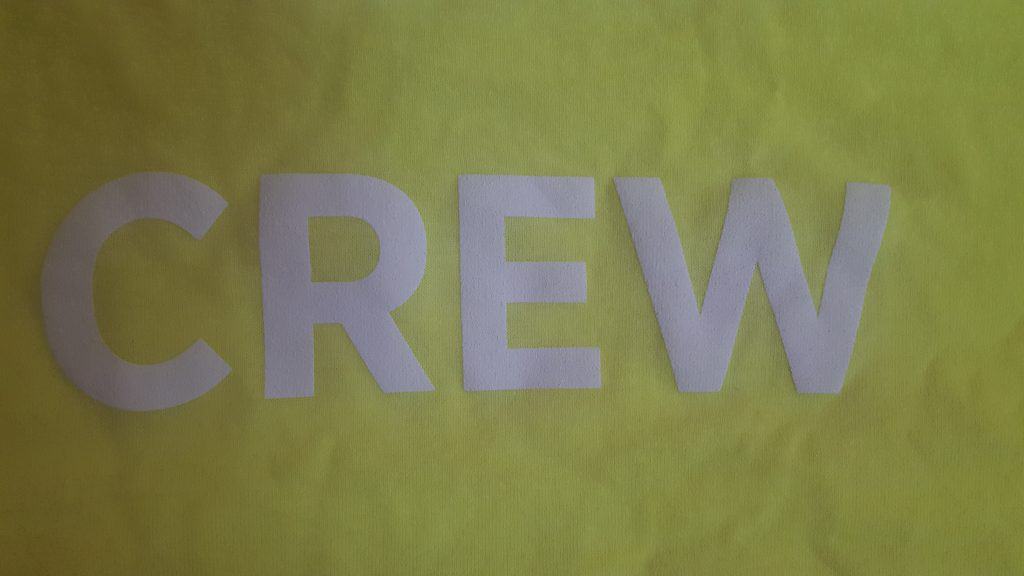

We printed the job and the customer was unhappy at the lack of contrast.

We could not really disagree.

As you can see it is tricky as in some light it looks ok, in others nearly unreadable.

We quickly reprinted the job (got shirts and printed four locations between 10AM and 5PM the same day.)

Lessons:

- Approved art does not mean you can just print jobs that then look bad.

- The customers count on us to be the experts and we are supposed to confront them if they are off track. This situation would have been very different if we had stopped the presses, said the contrast seemed insufficient and here’s a photo. If they then said ok, they would have paid for the job, I assure you.

- Enforcing approvals to make people pay will get your money but will nearly always lose you the customer. If a customer gives you $300K of work a year, are you going to make them pay for $1000 worth of bad shirts? Most of the people I see enforcing this type of thing have thousands of customers and they make them pay and just go on to getting a new customer.

- Medium greens, reds, purples, and blues can all be printed with white ink or black ink. Tough call in many cases and you have to make sure you got it right for the art in question. For example white might work with a border but not when the only thing printing.

- Your art department can only do so much, folks on the floor have to speak up when things are even questionable.

- When in doubt or when a large number of shirts is at stake, at least get a photo approved if not a physical sample. With the initial approval, if this job had been followed up with a photo, we would not have ruined 200 shirts and we would probably have got them to pay for new screens or an ink change.

The only silver lining of this might be that successful resolution of problems is often the glue that keeps your best customers coming back to you.

You are the BEST in the business!

I cannot agree more with this post, I always stress to our art department that it is our job to tell the customers something does not look right.. REGARDLESS if they approve it or not. Following up with a simple question will save your butt more times than not. Great post and follow through.