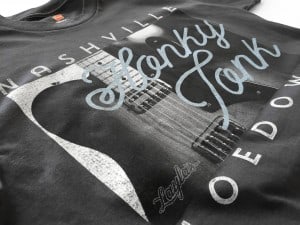

Curing Ink on Canvas

We received a panic inquiry from a supplier that we work closely with. They had a customer who claimed that they could not get their prints to cure on a canvas bag. We field many questions for our vendors, since printers love to blame the substrate for printing problems, so our vendors use us to…